Process Equipment and Spares

With over 30 years experience in the sugar industry, TL Technology's team of engineers will work in partnership with your team to select and size the best solution for your processes.

Our team will then supply and install, where needed, the recommended unit. Where spares are needed our engineers will suggest the best options to maximise the equipments efficiency.

Clarifiers

Syrup and liquor clarification systems designed and manufactured specifically to your productions needs.

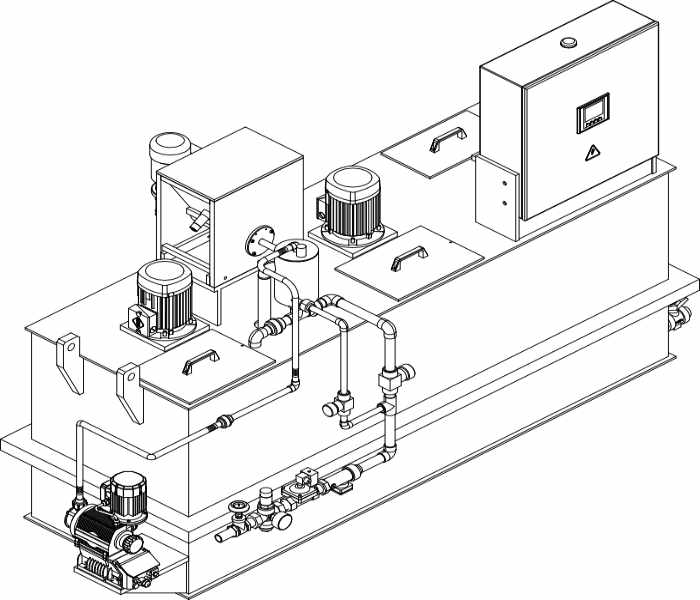

Flocculant Preparation Systems

Triple chamber continuous flow system used for the preparation of polymer solutions. Processing of liquid and powder polymers (0.05 - 0.5%) solutions. Optional PLC programmable controller module. Storage tank capacity of 400, 1000, 2000, 4000, 6000 and 8000 lts.

Spray Nozzels

Standard and specifically designed spray nozzles. Comprehensive range of industrial, Tank Cleaning static, rotary and jet spray heads and static self cleaning filters of all aspects of spray technology. Supplied in a variety of materials including: brass, stainless steel and plastics. Spray can be Flat fan, Hollow Cone, Solid Cone, Misting, Air Atomising and CIP

Plate heat exchangers

Gasketed plate pack design heat exchangers small size, light weight and high efficiency in transferring heat. Flows from 0.03 m3/min to 39.75 m3/min

Pumps

High precision inverter controlled positive displacement pumps, diaphragm pumps and centrifuge pumps.

Nutsche Filters

Used to determine the purity in syrup in centrifuges before and after the wash. Measure the losses in molasses.

RF Probes

The digital ratio frequency probe has applications in the sugar industry for the measurement of prix of massecuites in pans or of liquors.

Speciality Glass Materials

Speciality glass materials, optical windows, glass wafers, optical filters.

High temperature resistance of up to 500 ºC with excellent optical quality, low absorption and exceptionally high chemical resistance

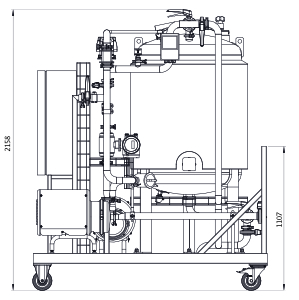

Clean In Place systems (CIP)

Automatic and manual systems to clean tanks, lines. Highly effective in the cleaning (boiling) of evaporators and pans. One tank holds the cleaning solution while the other tank collects the wash solution.

Semi automatic bagging systems

TL Technology are a supplier of semi-automatic systems for filling and closing bags.

Great precision systems from the Big Bag packing systems to bagging machines that can work filling 5kg to 50 kg bags.

With the 5kg to 50kg units change occurs with minor adjustments to the machine. Bagging can be up to 200 bags/hr gross weight, up to 600 bags/hr net weight or up to 1000 bags/hr with duplex HiSpeed Net weighing system.

On the big bag system packing can be up to 40 bags/hr when including the bag transport belt conveyor.

Precision Woven Mesh

TL Technology are a supplier of woven wire mesh, synthetic filter fabrics and allied products used in the filtration, separation processes.

(DSM screen) Sieve bend screens

Static and vibrations run down screens supplied in stainless steel. As the juice/liquor passes through the screens mesh stay in the surface, and as this accumulating mass increases in weight/volume, gently slides down the screen surface. The static screen versions has it screen rigidly fixed in position whereas the vibrating, more efficient unit, has it mounted to enable a small motor to vibrate it.